A bill of material template is a tool to create a list of all the requisite materials you need to build your product. This tool is an instruction manual that helps you avoid production delays and waste.

Table of Contents

What is a bill of materials?

A bill of materials is a document manufacturers use to list all the materials and components required to create a product. This document is usually used in manufacturing or engineering projects that involve several stages to build a product.

Furthermore, a bill of materials helps you add efficiency to the supply chain. It also ensures that the materials you require for manufacturing are always on hand. The document shows what you need to keep the production line moving forward and avoid delays and extra warehousing costs.

The common types of bill of materials:

Here are the most common types of BOMs;

Modular BOM

In this type of BOM, the components are listed hierarchically to explain all sub-assemblies within the completed product. In a single level of BOM, there is one level of sub-assemblies while a multi-level BOM contains multiple levels.

Engineering BOM

This type of BOM displays the product components as designed by the engineers. Instead of simply listing the required materials, this BOM reflects the engineering needs.

Manufacturing BOM

In a manufacturing BOM, all the physical parts required to successfully manufacture a product are listed. It focuses on the tangible parts and how they relate to each other instead of the engineering design.

Configurable BOM

The configurable BOM is used for products that offer several options or arrangements and depends on a modular BOM structure. For this type of BOM, most organizations use “configurator” software as users will have to reorganize part combinations for each variation.

Equipment BOM

This BOM states all the tools and equipment required to make a product instead of underlying materials. Likewise configurable BOM, it also uses a modular structure.

Reasons for using a bill of materials template:

The main reason for using a bill of materials template is that it helps determine the inventory stock needed when producing products. This document is crucial if you want efficient inventory control. Another reason is that it enables you to assess waste as you need the essential components for the final project. With the help of a template, you can determine cost-effective ways to outsource materials so you better manage your production costs.

When to use a bill of materials template?

The Bill of Materials is an essential document that benefits your business in many ways. It helps the manufacturing operators with production planning and at the production line. The template affects your business’s key areas, including operations management, inventory management, and supply chain. In addition, the information collected in the bill of materials allows the inventory management to carry the inventory necessary for production.

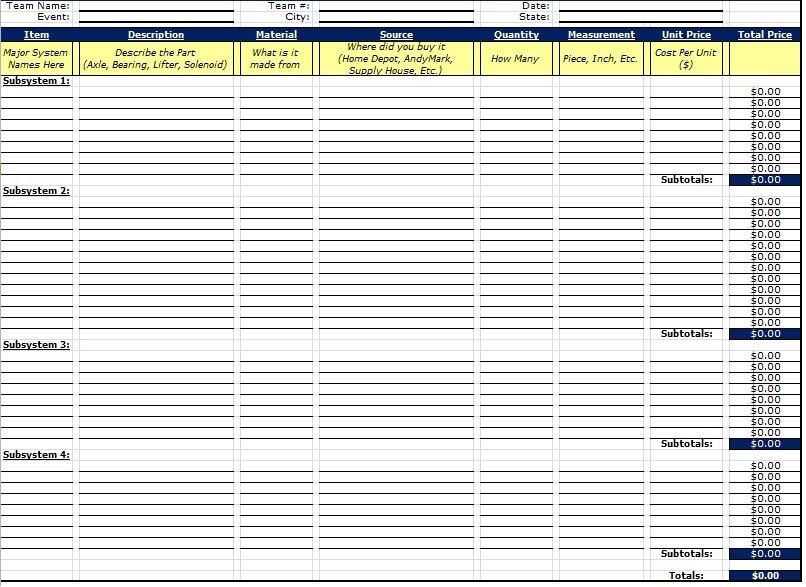

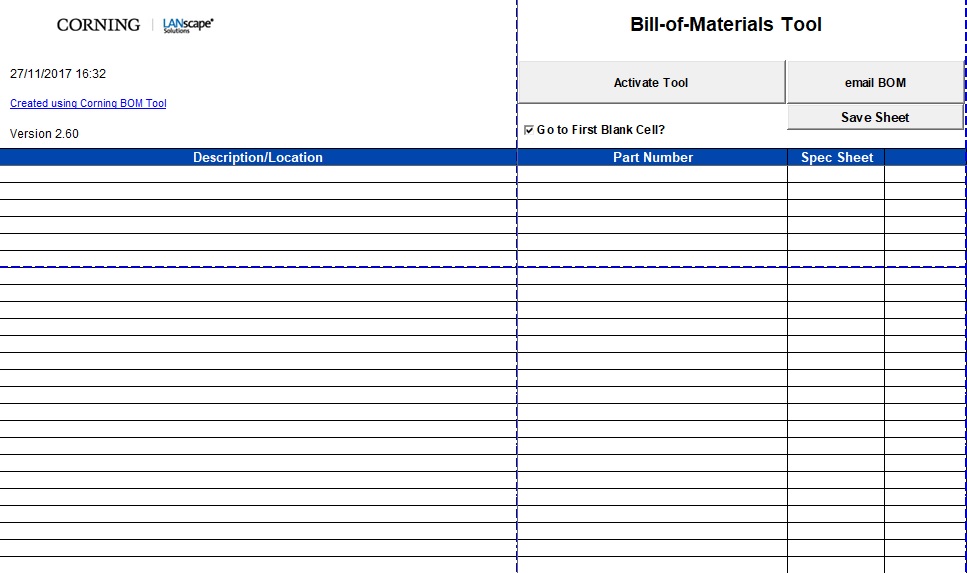

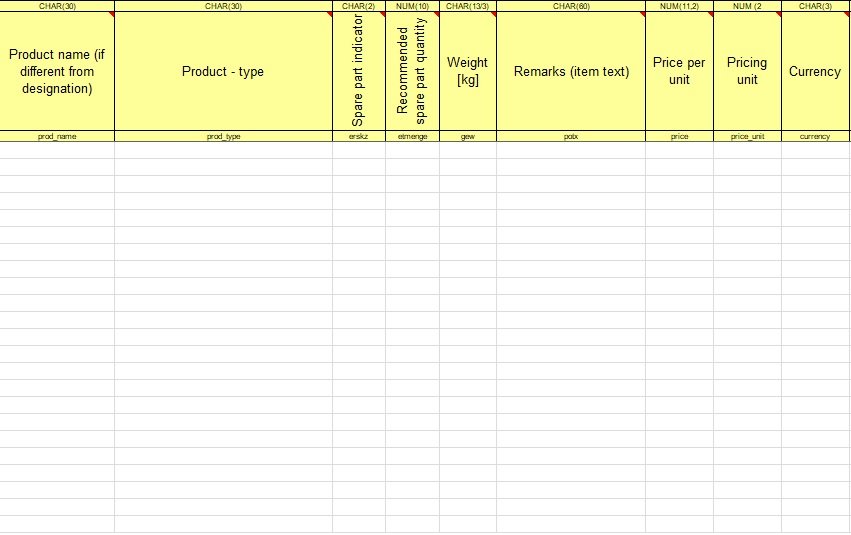

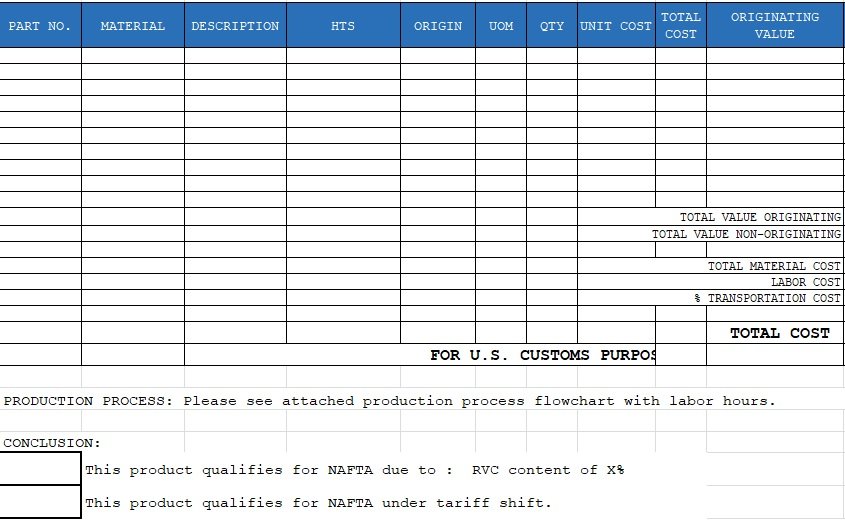

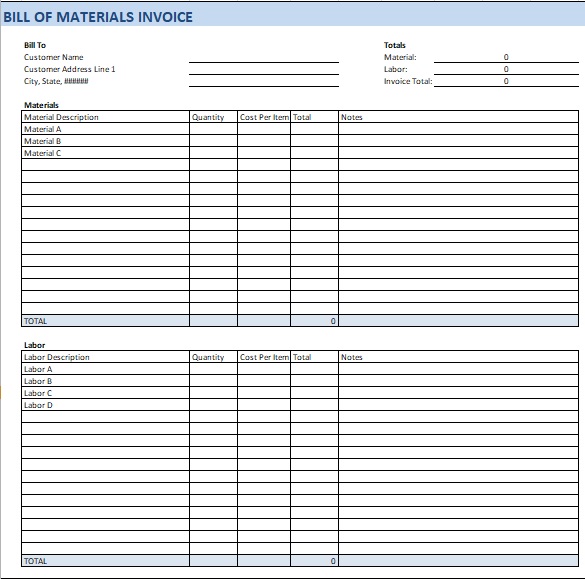

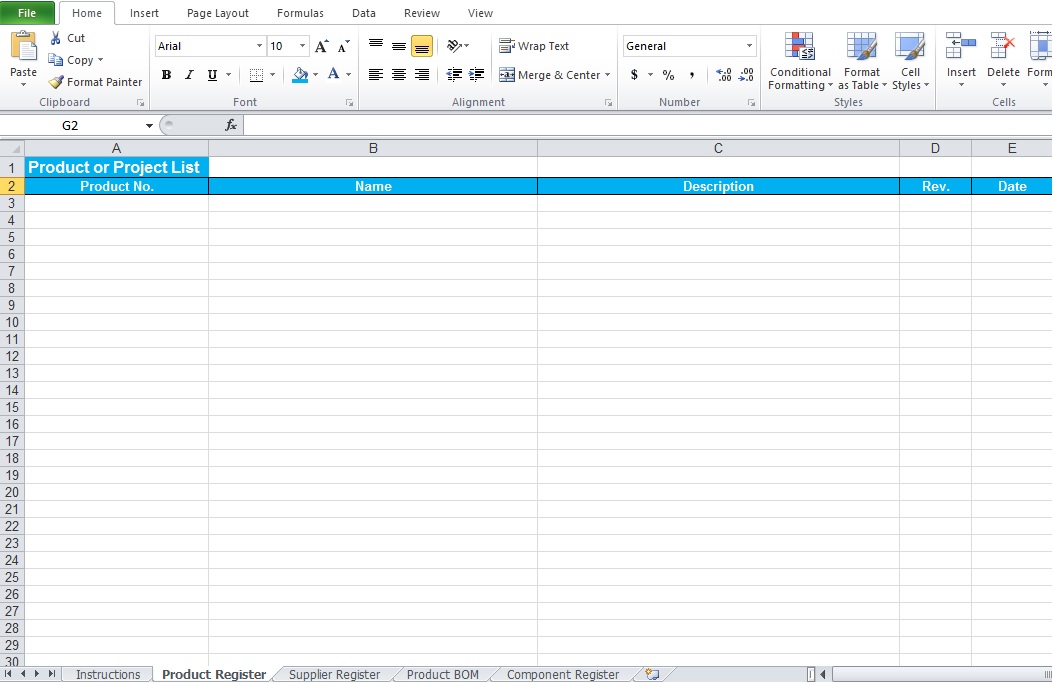

Bill of Materials Template Free

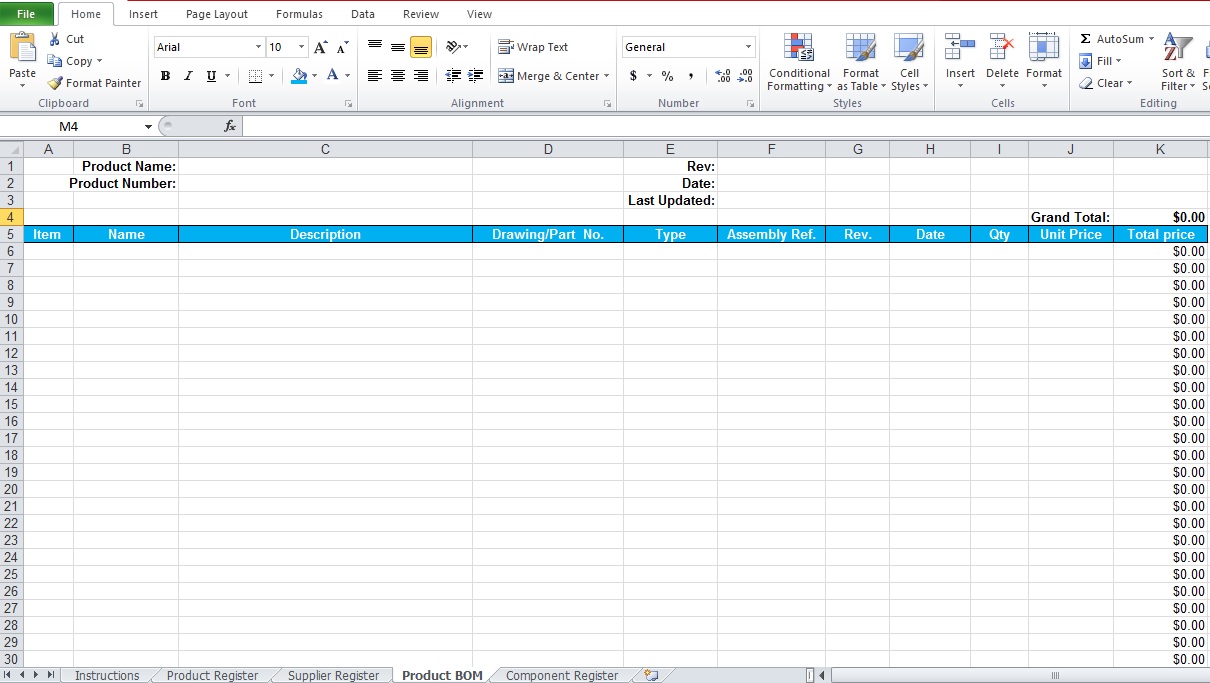

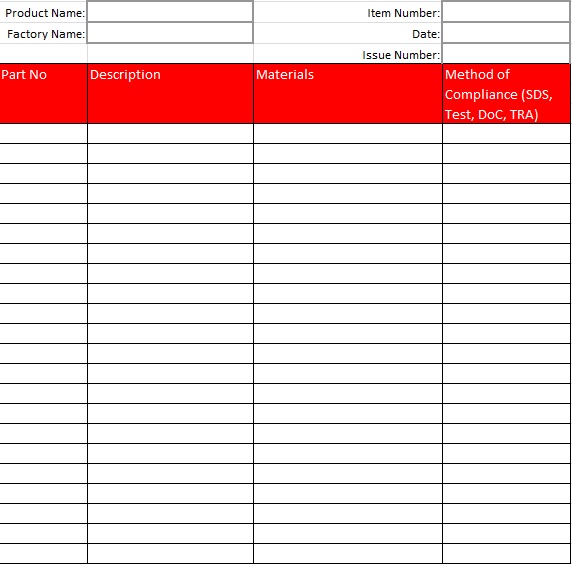

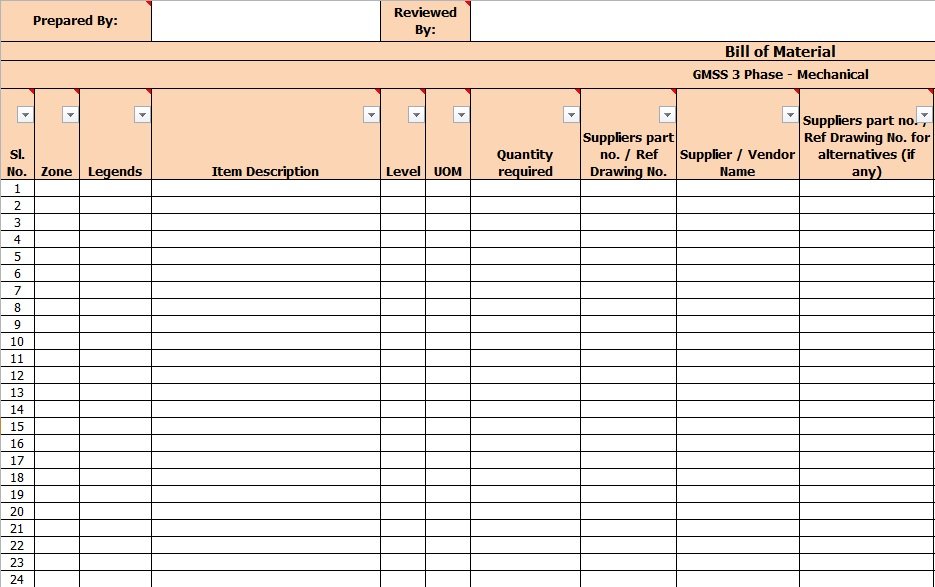

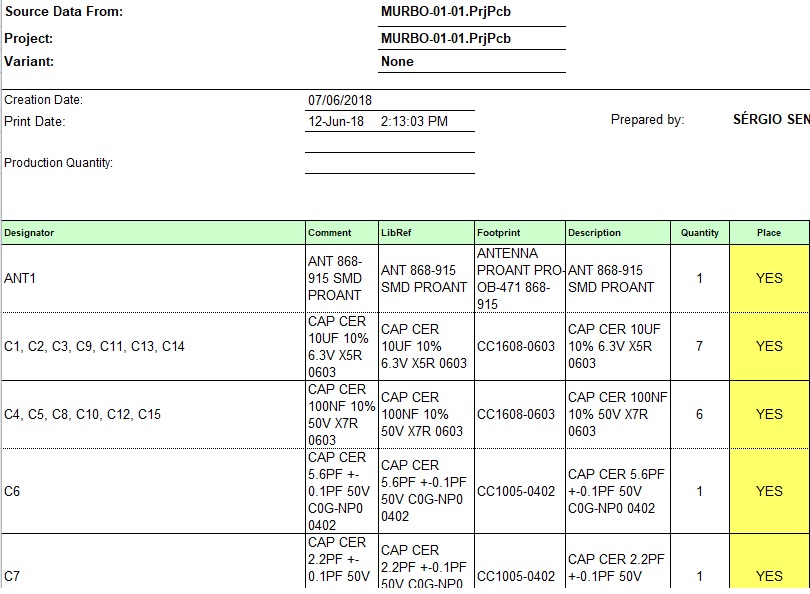

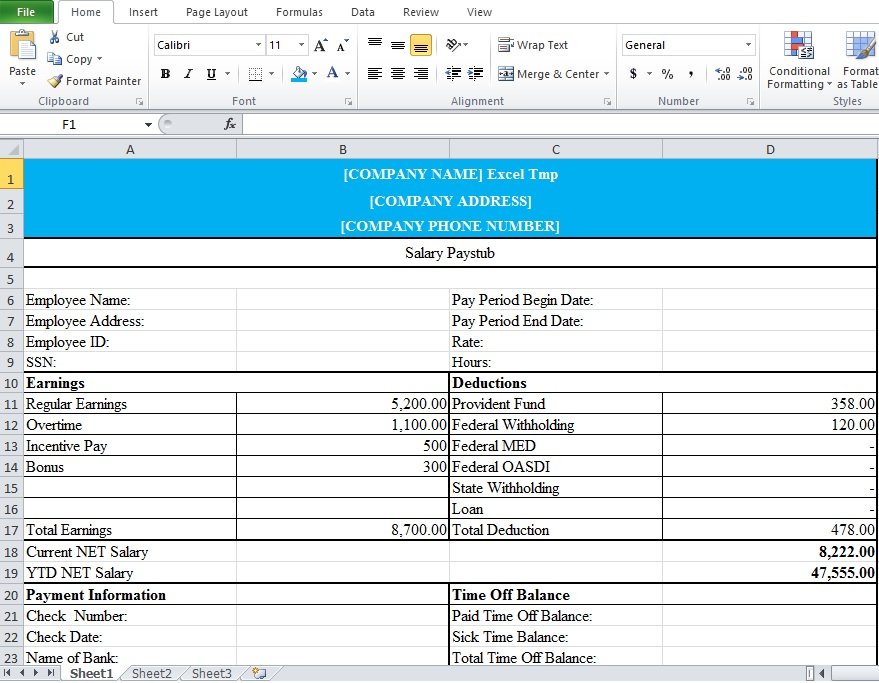

Bill of Material Format in Excel

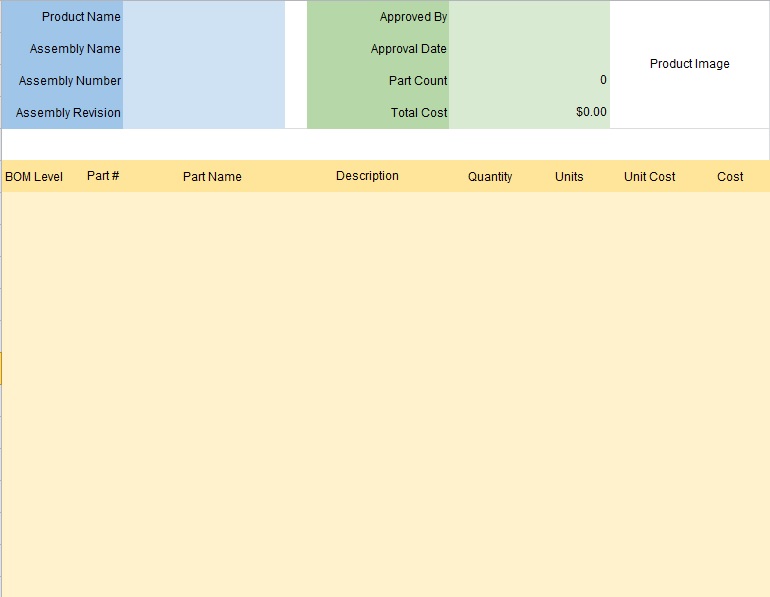

Bill of Material Template

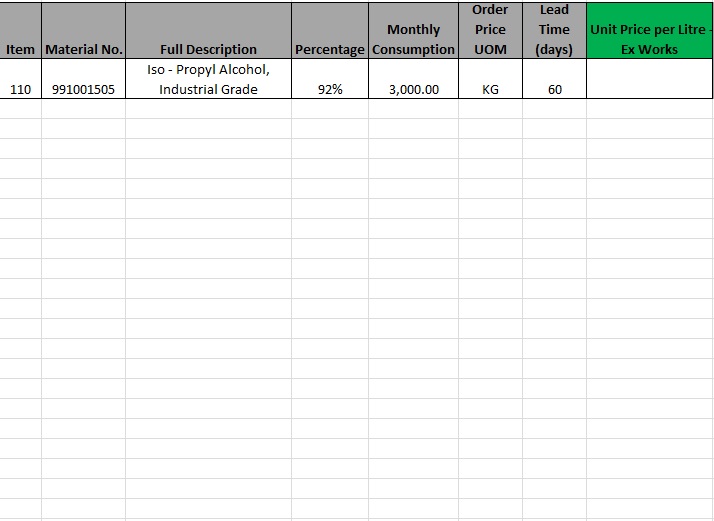

Bill of Materials Example

Bill of Materials Spreadsheet

Bill of Materials Template Excel

Construction Bill of Materials Template

Excel Spreadsheet Bill of Materials

Manufacturing Bill of Materials Template

Multi Level BOM Excel Template Free

Printable Bom Template

What to include in a bill of materials?

Depending on the product or industry, the bill of materials template is created. Each type of BOM contains the same basic information about the materials required for the creation of the product. Include the following elements to make an effective bill of material template;

- The name of the product

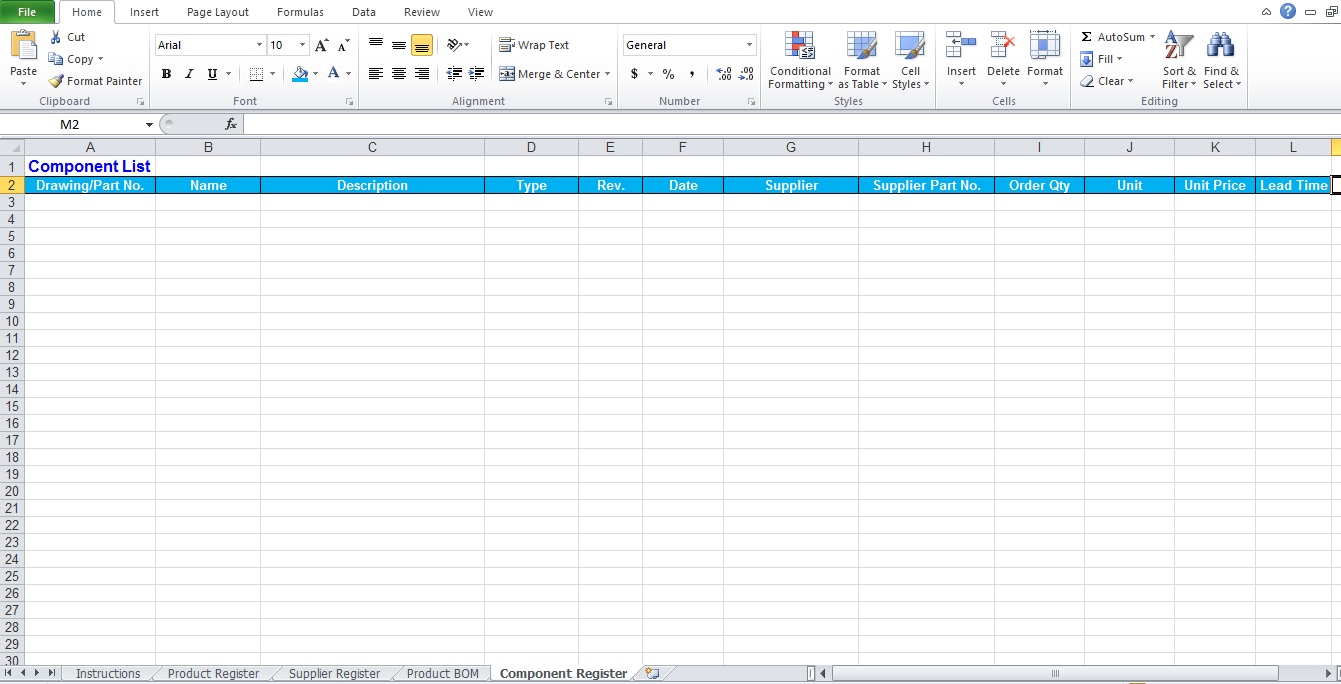

- The name of the material

- For each of the materials, components, or parts, the assigned part number that makes it easier to locate.

- Provide a precise description of each material, component, or part

- For each of the materials, components, or parts, mention a list of required quantities

- State the proper metric or unit of measure for each

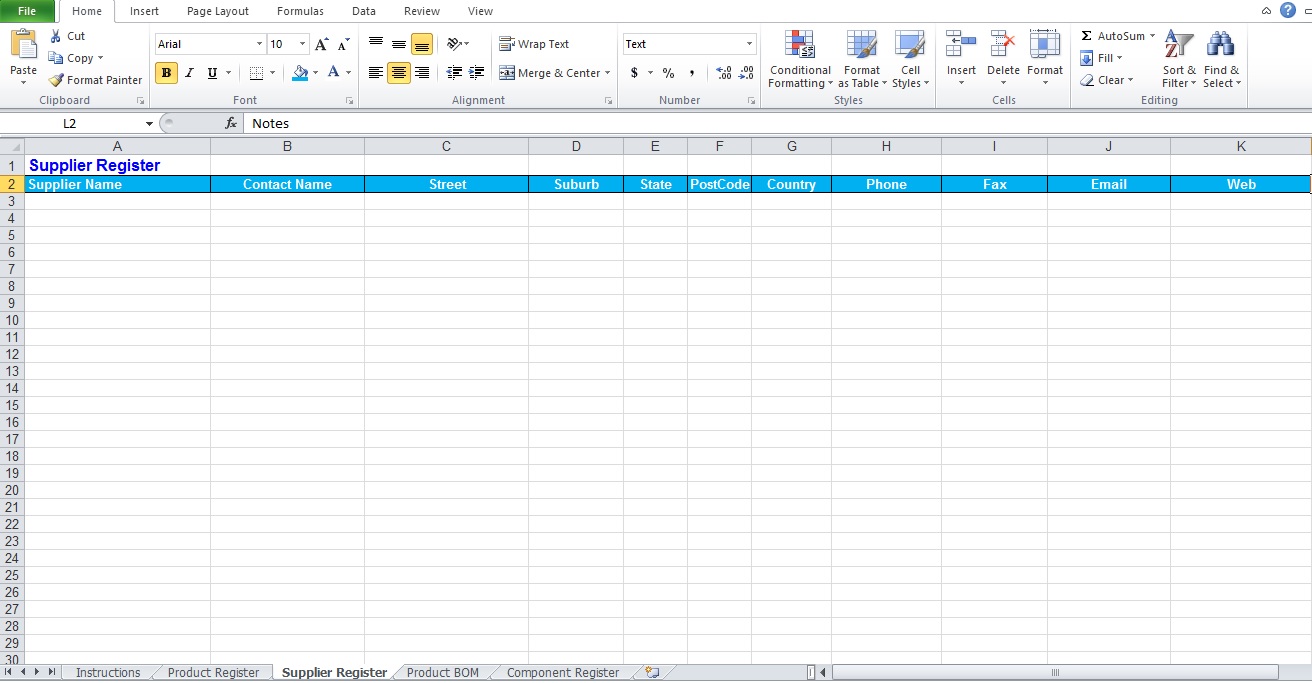

- If you want to procure your materials, components, or parts from external vendors then provide the information about the vendor or supplier like their names and contact details

- State the cost of each unit and the total cost for each of the materials, components, or parts

FAQ’s

Before kicking off your project, you should create a BOM template. It makes sure that all the team has the required information that they need for project completion.

Anyone involved in the following should use the BOM;

1- Raw materials

2- Production process

3- Manufacturing process

4- Resource planning

5- Working with finished goods